TECHNOLOGY

The SEVAR belt dryer is operated for convective drying of watercontaining products such as sewage sludge and digestate. The drying temperatures of the circulating drying air are in the range of 70 - 130 °C, depending on the type of heating. Further applications for the double-path belt dryer are the drying of wood chips, bark, grass, leaves, green cuttings, hulls and husks as well as animal waste, pomace, press residues, biowaste and animal faeces.

DRYING PROCESS

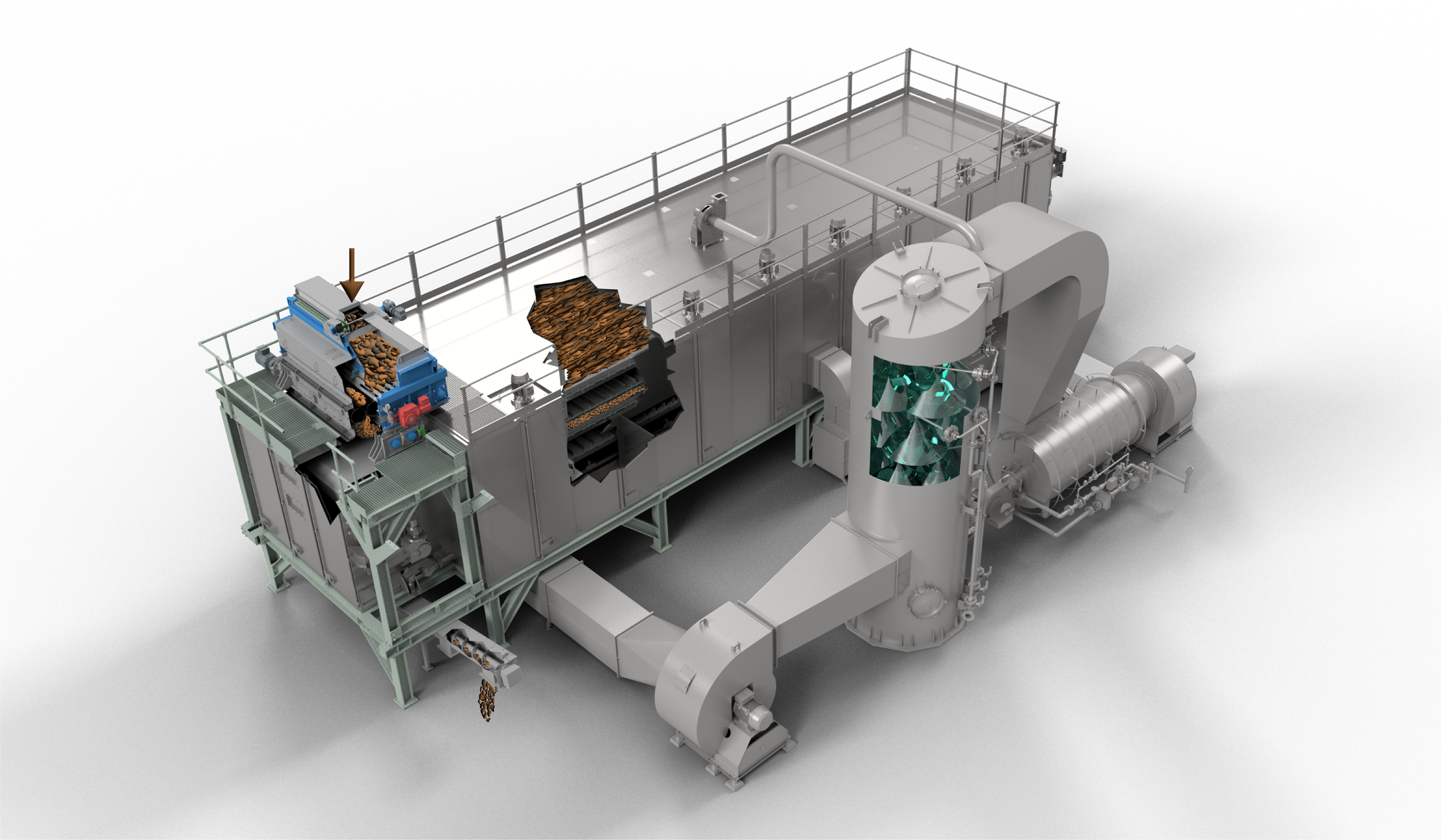

The belt dryer is of modular design, it consists of an inlet/outlet module, a number of dryer modules designed according to the throughput or the water evaporation, and a return module. Horizontally the dryer is traversed by two perforated stainless steel conveyor belts arranged one above the other.

The sewage sludge, mechanically dewatered to 18 - 30% dry solids, is continuously and uniformly distributed on the dryer belt via the inlet unit (distribution / dosing / roller press). The roller press - consisting of two counter-rotating grooved rollers - forms the sewage sludge into strands with the effect of increasing the surface area of the material to enhance the heat transfer and water evaporation.

As the wet material is transported on the upper dryer belt through the dryer modules, the drying temperature increases and the residual moisture in the material decays. The lower dryer belt transports the material back to the discharge screw. In the front section of the dryer the dry product cools down. At the outlet of the discharge screw the temperature is approx. 40 °C.

In general the belt dryer is used for full drying up to 90% dry solids.

The product is dried gently, as the material is subjected to little mechanical stress. This minimizes dust formation. The temperatures and the negative pressure in the dryer modules are measured and the belt speed is controlled. This ensures effi cient drying time and constant product quality.

ADVANTAGES

- Slow moving parts: Gentle drying process

- Low dust formation: Safe atmosphere

- Low drying temperatures: 70 - 130 °C

- Perforated dryer belt made of stainless steel 304 / 316L: High corrosion and temperature resistance, long service life

- Easy accessibility

- Belt speed / retention time variable: 60 - 180 min

- Modular design: Expandability for higher throughput / water evaporation capacity

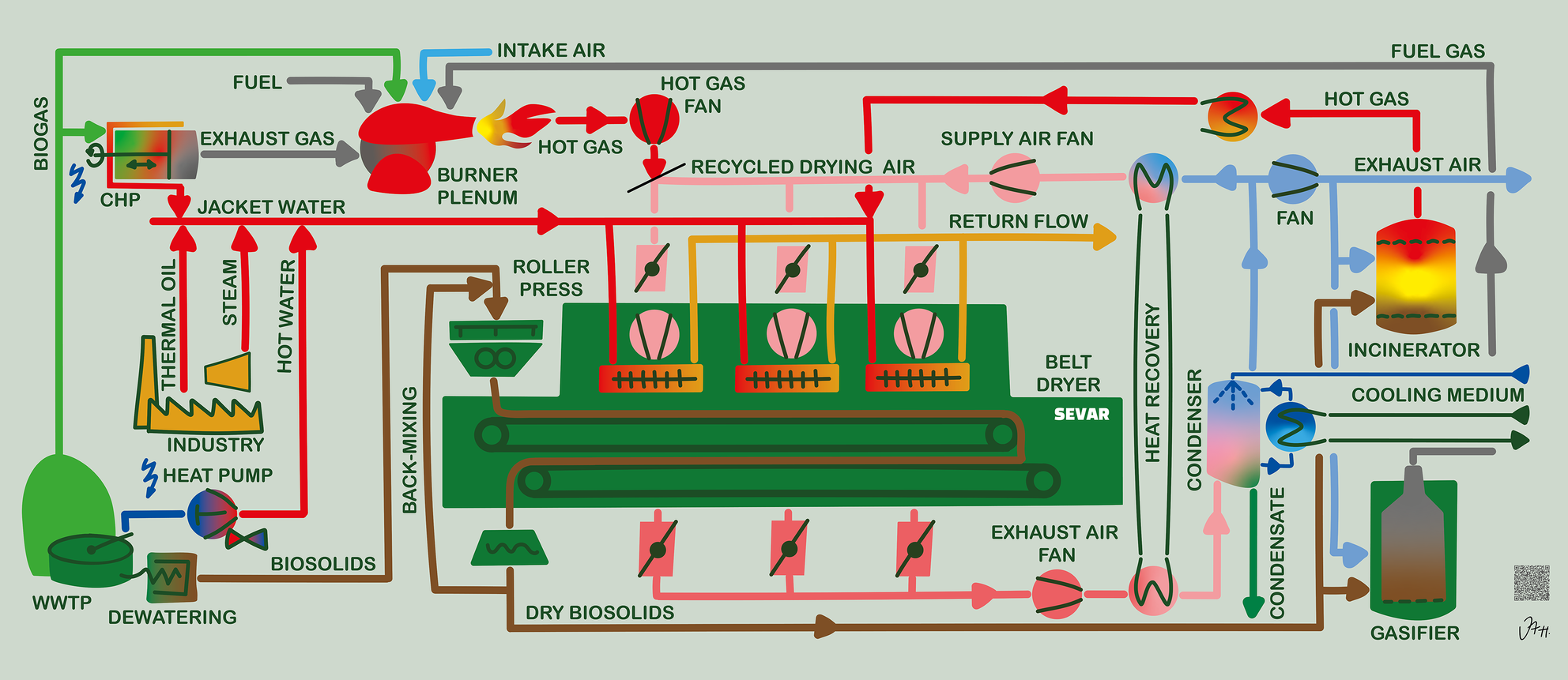

- Various heating options

- Energy optimized: Heat recovery

- High thermal efficiency: Optimized process air circulation

- Continuous operation: Low operating and maintenance costs

- Operation with negative pressure: Low odor emission

Technical Description Belt Dryer download