Indirect heating

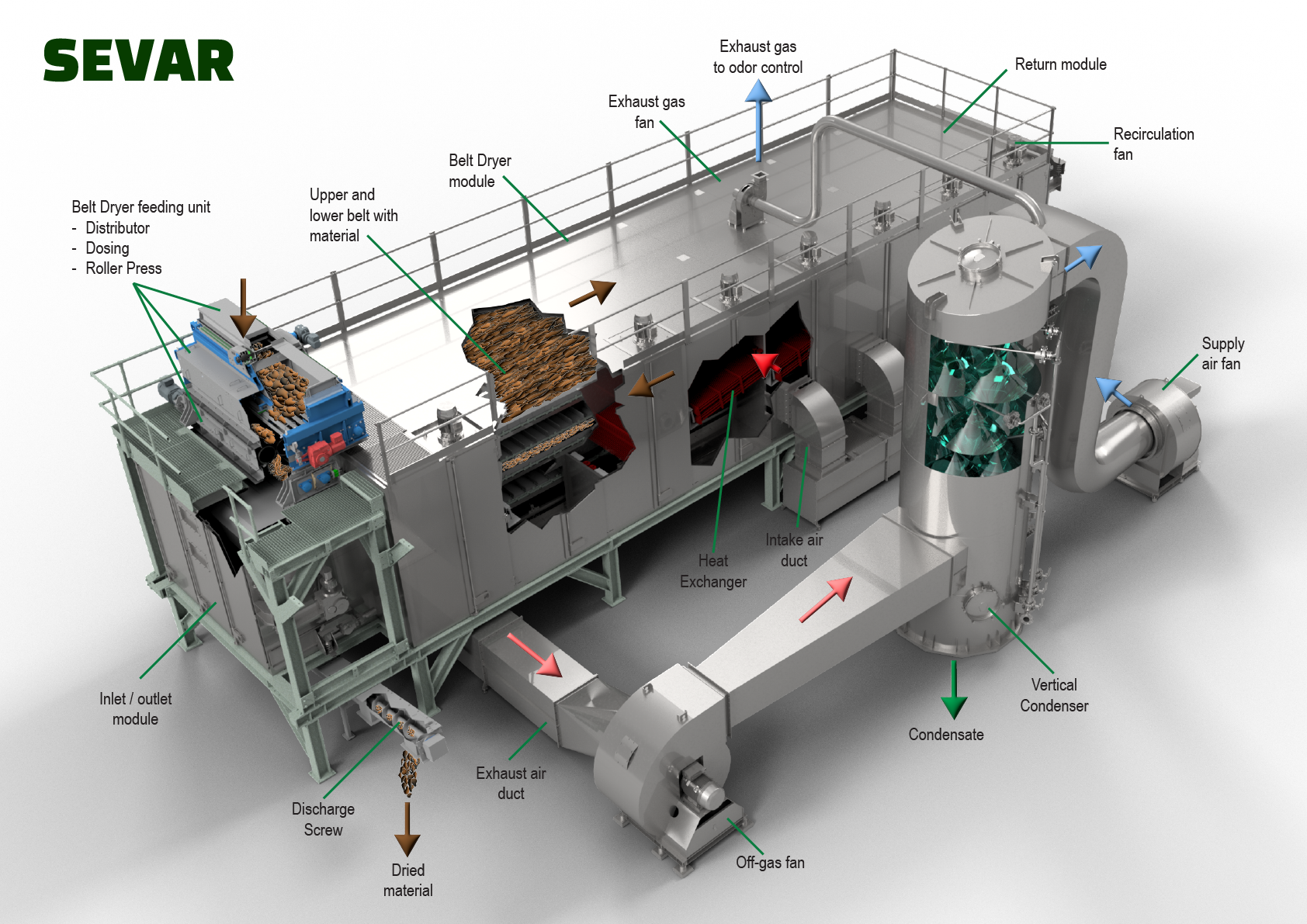

The modular design of the belt dryer enables its adaptation to a wide range of site conditions.

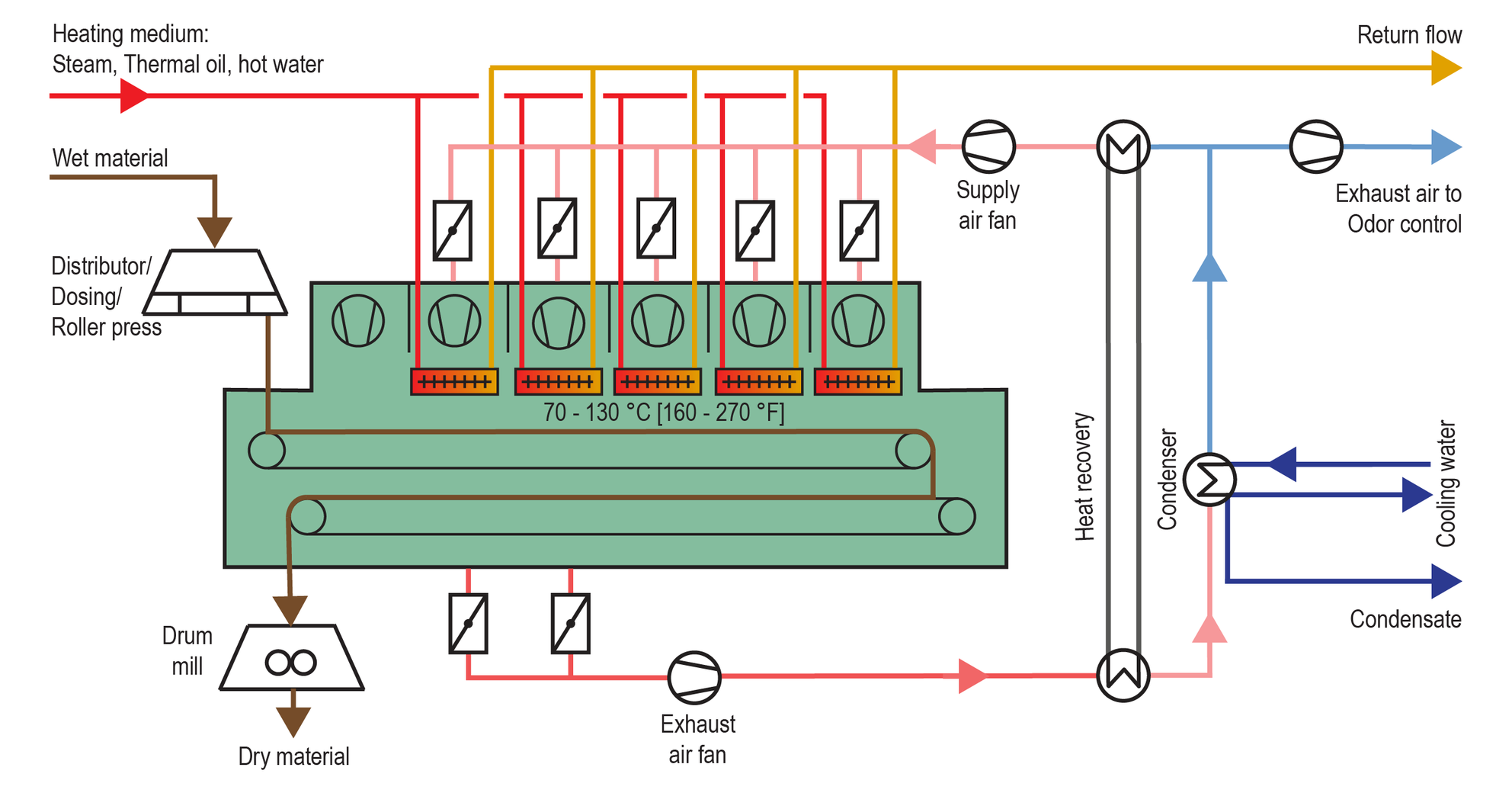

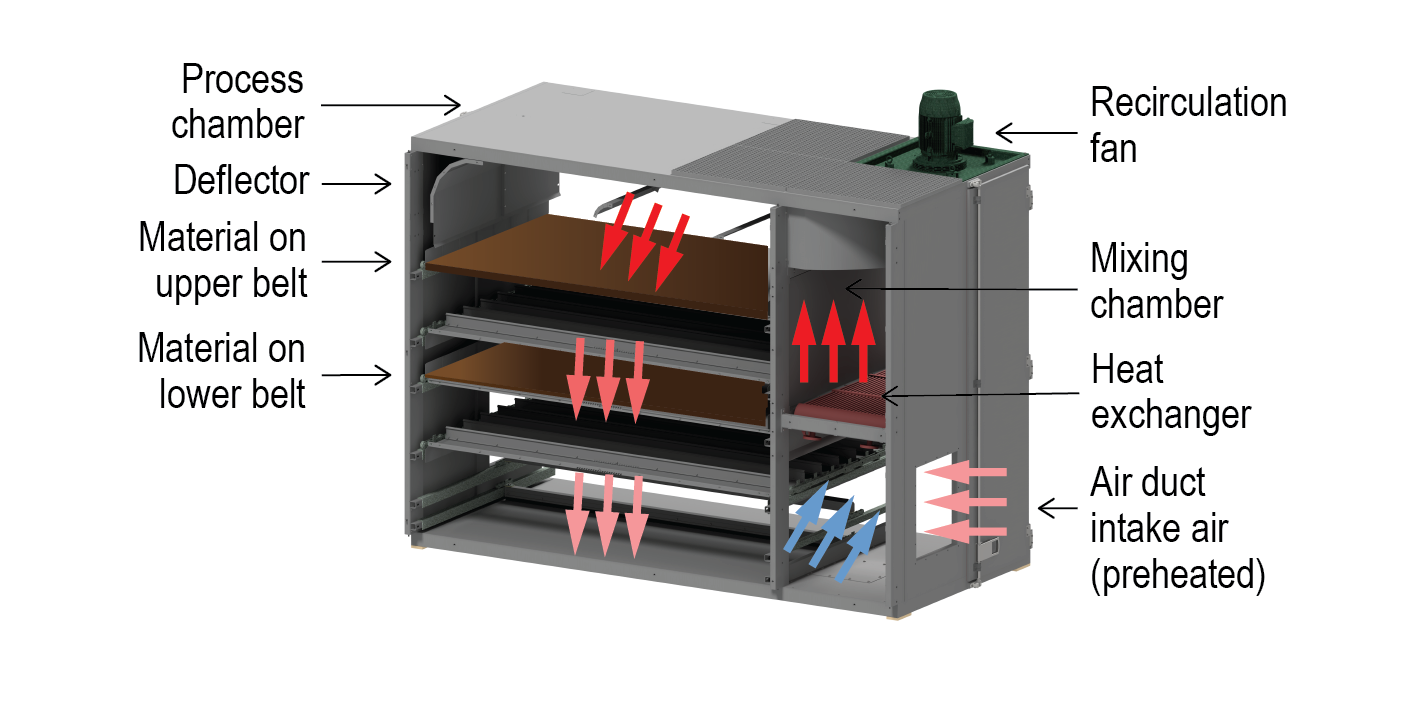

Indirect heating of the belt dryer is technically implemented with internal heat exchangers fed with hot water, steam or thermal oil. Jacket water of a CHP unit is used as heating medium. The hot exhaust air of the belt dryer as well as the final effluent of a WWTP contain a thermal energy potential for drying. The operation of a heat pump uses this energy potential to generate hot water.

A combination of direct and indirect heating is technically possible.